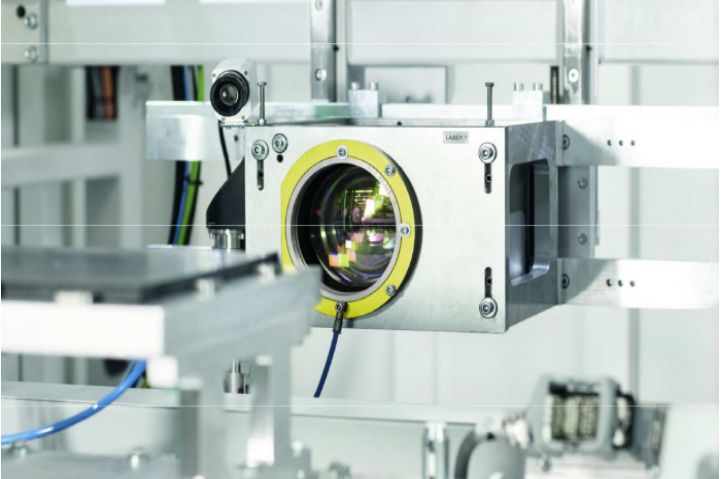

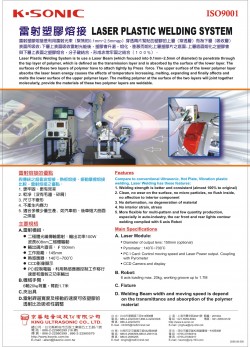

Laser Plastic Welding Machine

Laser Welding of Plastics

Laser welding of plastics provides a high-precision, clean, and vibration-free method for joining sensitive plastic components. It is ideal for applications requiring excellent cleanliness and tight seals, especially in medical, automotive, and electronics industries.

Key Benefits:

-

No vibrations or shocks

-

Minimal heat-affected zone (HAZ)

-

No contamination to components

-

Cleanroom-compatible

-

Strong, leak-proof welds

| Contour | Mask | Simultaneous | Quasisimultaneous |

|---|---|---|---|

| 2D and 3D contours | 2D contours | 2D and 3D contours | 2D and limited 3D contours |

| Very flexible technique | Very fine welds possible | Short welding times | Very flexible process with short welding times |

| Ideal for large parts and many variants | Ideal for micro and small parts | Ideal for very high production numbers and complex weld seam | Ideal for high numbers and many variants |

| Limited process control, no displacement (penetration) | Limited process control, no displacement, small parts | High cost, not flexible | Limited part geometry |

| HPDL / Nd:YAG / Fiber | HPDL | HPDL | HPDL / Nd:YAG / Fiber |

Download Laser Welding Concept PDF

-

Sales Line

+603-6151 2682 -

Fax Line

+603-6151 2683

-

Whatsapp

+6012-329 6880 -

Enquiry Now

myksonic@gmail.com